Image Source: Google

In the world of manufacturing, precision is key. Every millimeter matters, and the smallest error can lead to significant repercussions down the line. This is where laser manufacturing services come into play, offering unparalleled accuracy and efficiency in the production of a wide range of products. Let's delve into the realm of laser manufacturing services and explore how this cutting-edge technology is shaping the future of manufacturing. Refer Link: https://www.lasermicromachining.com/.

The Role of Laser Manufacturing Services

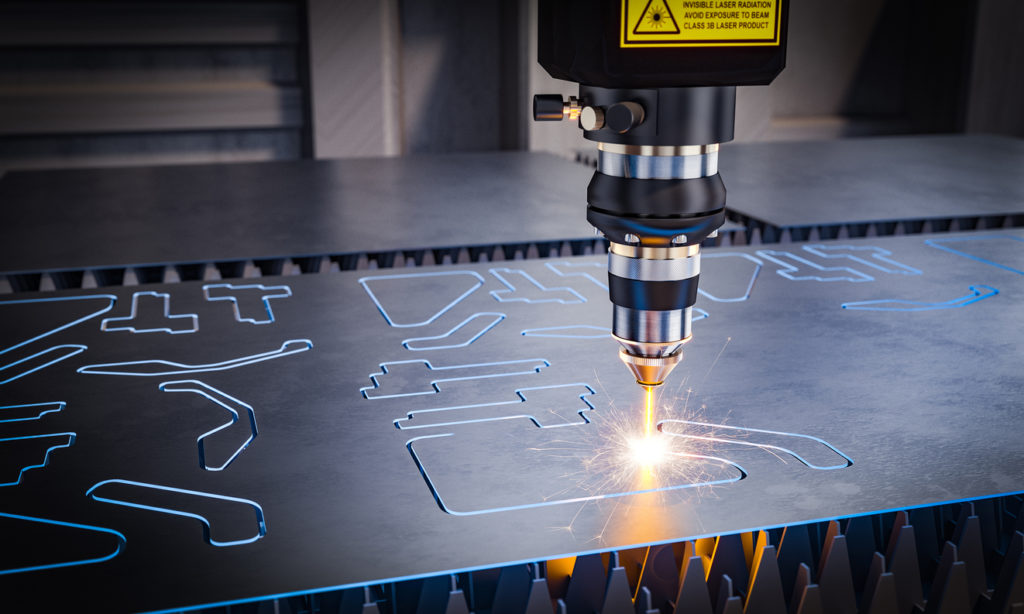

Laser manufacturing services utilize laser technology to cut, drill, weld, and mark materials with exceptional precision. This technology has revolutionized the manufacturing industry by allowing for intricate designs and highly accurate production processes. Some of the key roles of laser manufacturing services include:

1. Precision Cutting

- Laser cutting allows for precise cutting of materials such as metal, plastic, wood, and glass.

- It produces clean edges without the need for extensive finishing processes.

- This precision is essential for industries such as aerospace, automotive, and electronics.

2. Welding

- Laser welding provides strong, precise welds with minimal heat-affected zones.

- It is used in industries where high precision and quality are paramount.

- Laser welding is particularly well-suited for joining dissimilar materials.

3. Marking and Engraving

- Laser marking and engraving offer permanent markings with high precision and resolution.

- These processes are commonly used for branding, part identification, and traceability.

- Laser marking is highly versatile and can be done on a wide range of materials.

Benefits of Laser Manufacturing Services

The use of laser manufacturing services offers a multitude of benefits for manufacturers looking to achieve high levels of precision and quality in their products. Some of the key benefits include:

1. Precision and Accuracy

- Laser technology allows for micrometer-level precision in cutting, welding, and marking.

- Manufacturers can achieve tight tolerances and intricate designs with ease.

- This precision leads to higher quality products and reduced waste.

2. Speed and Efficiency

- Laser manufacturing services are known for their high speed and efficiency in production processes.

- Complex designs can be produced quickly and without the need for multiple setups.

- This efficiency results in shorter lead times and increased productivity.

3. Versatility

- Laser technology can be used on a wide range of materials, including metals, plastics, ceramics, and composites.

- It is suitable for various industries, from aerospace and automotive to medical and electronics.

- This versatility makes laser manufacturing services a go-to solution for diverse manufacturing needs.

Applications of Laser Manufacturing Services

The versatility and precision of laser manufacturing services make them essential for a variety of industries and applications. Some of the key applications include:

1. Aerospace

- Laser cutting and welding are used to produce intricate components for aircraft and spacecraft.

- The high precision of laser technology ensures safety and reliability in aerospace applications.

2. Automotive

- Laser cutting is utilized in the production of automotive parts with complex shapes and designs.

- Laser welding provides strong and durable welds for vehicle components.

3. Medical

- Laser marking is used for part identification and traceability in medical device manufacturing.

- Laser cutting and welding are employed in the production of surgical instruments and implants.

Future Trends in Laser Manufacturing Services

As technology continues to advance, the world of laser manufacturing services is evolving to meet the growing demands of manufacturers. Some of the key trends shaping the future of laser manufacturing services include:

1. Additive Manufacturing

- Laser technology is being used in additive manufacturing processes such as 3D printing.

- This allows for the production of complex geometries and customized parts with high precision.

2. Green Manufacturing

- Laser manufacturing services are becoming more environmentally friendly with the adoption of green laser technology.

- This technology reduces energy consumption and waste generation, making it a sustainable option for manufacturers.

3. Automation

- Automation is playing a significant role in streamlining laser manufacturing processes and increasing efficiency.

- Robotic systems are being integrated with laser technology to enhance productivity and reduce labor costs.

Overall, laser manufacturing services are at the forefront of precision manufacturing, offering unmatched accuracy, efficiency, and versatility for a wide range of industries. As technology continues to advance, we can expect to see even more innovative applications of laser technology in the manufacturing world.